Product and Ordering Information

Table 1 (style)

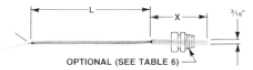

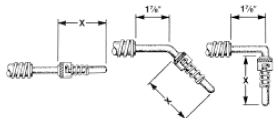

| Figure 1 | Bayonet with stainless steel armor |

|

|

| Figure 2 | Bayonet with stainless steel overbraid |

|

|

| Figure 3 | Rigid tube with stainless steel armor |

|

|

| Figure 4 | Rigid tube with stainless steel overbraid |

|

|

| Figure 5 | Rigid tube bayonet with male plug (only option “M” in Table 5 may be specified |

|

|

| Straight |

|

| Assemblies in figures 1-5 are available with straight, 45° or 90° angle configuration. Select in Table 1. |

|

Order Code |

Configuration | ||

| Straight | 45° | 90° | |

| Figure 1 | R111 | R145 | R190 |

| Figure 2 | R211 | R245 | R290 |

| Figure 3 | R311 | R345 | R390 |

| Figure 4 | R411 | R445 | R490 |

| Figure 5 | R511 | R545 | R590 |

Table 2 (sensing element options)

| Sensor Type | Order Code | |

| 2-Wire* | 3-Wire* | |

|

100ohm Platinum .00385 T.C. (DIN 43760) (Most commonly used) |

A2 | A3 |

| Notes: |

For dual element insert a “2” in front of order Code. Example: 2A3 |

|

Bayonet and Rigid Assemblies

Table 3

Temperature Range Options

| Temperature Range | Order Code |

|

-50 to +260°C -50 to +500°F |

L |

| -50 to +400°C -50 to +750°F | S |

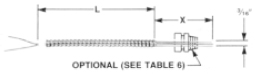

Table 4

Dimension Option

| “X” and “L” Lengths | Order Code |

|

Refer to Figures 1-7 and specify the lengths of “X” and “L” in inches. Insert in ordering sequence. See “How To Order” |

|

Table 5

End Terminations

|

Insulated Leads-Striped |

B |

|

No. 8 Spade Lugs |

L |

|

Male Plug |

M Required for Figure 5. Optional for others. |

|

1/2″ BX Connector |

BX |

|

1/2″ BX Connector w/ #8 Lugs |

BXL |

Table 6

Options

| Style | Order Code |

| 1/8″ npt brass compression fitting for Figures 3 and 4 | B |

| 1/8″ npt stainless steel compression for Figures 3 and 4. | S |

| Mating female connector for end termination “M” in Table 5 | F |

How to Order

Make a selection from each table and specify “X” and “L” dimensions as shown below. Insert hyphens only where indicated.

| Style | – | Sensing Element | – | Temp. Range | – | Dimensions | – | Terminations | – | Options | ||

| R111 | A3 | L | (X) | Specify

in Inches |

(L) | M | F | |||||

| Table 1 | Table 2 | Table 3 | Table 4 | Table 5 | Table 6

(optional) |

|||||||

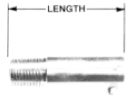

Bayonet Adapters

Table 13

| Thread | Length | Part Number |

|

1/8NPT 1/8NPT 1/8NPT 3/8-24 3/8-24 3/8-24 |

7/8″ 1-3/8″ 2-1/2″ 7/8″ 1-3/8″ 2-1/2″ |

3001-1 3001-2 3001-3 3001-4 3001-5 3001-6 |

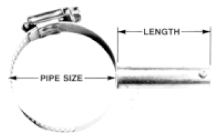

| Part Numbers | |||||||||

| Adapter Lengths | Pipe Clamp Sizes (IPS) | ||||||||

| 1/2″ | 3/4″ | 1-1/2″ | 2″ | 2-1/2″ | 3″ | 3-1/2″ – 4″ | 5″ | 6″ | |

| 1.875″ Standard | 3002-1 | 3002-2 | 3002-3 | 3002-4 | 3002-5 | 3002-6 | 3002-7 | 3002-8 | 3002-9 |

| 2-1/2″ | 3003-1 | 3003-2 | 3003-3 | 3003-4 | 3003-5 | 3003-6 | 3003-7 | 3003-8 | 3003-9 |

| 3″ | 3004-1 | 3004-2 | 3004-3 | 3004-4 | 3004-5 | 3004-6 | 3004-7 | 3004-8 | 3004-9 |

| 3-1/2″ | 3005-1 | 3005-2 | 3005-3 | 3005-4 | 3005-5 | 3005-6 | 3005-7 | 3005-8 | 3005-9 |

| 4″ | 3006-1 | 3006-2 | 3006-3 | 3006-4 | 3006-5 | 3006-6 | 3006-7 | 3006-8 | 3006-9 |

| 5-1/4″ | 3007-1 | 3007-2 | 3007-3 | 3007-4 | 3007-5 | 3007-6 | 3007-7 | 3007-8 | 3007-9 |

For New Installations:

The following formula may be used to determine the “X” dimensions of bayonet RTD.

For Threaded Adapters:

X = Depth of hole + adapter length + 1/2″.

For Pipe Clamp Adapters:

X = Adapter length + 3/4″

(This formula assumes the sensor is in surface contact with the pipe.)