Product and Ordering Information

Table A

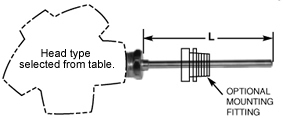

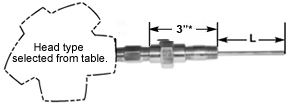

| Figure 1 |

RTD Assembly without Process Fitting |

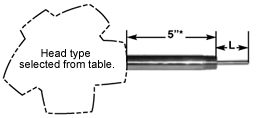

Figure 4 |

Spring-Loaded RTD Assembly with 1/2″ NPT Pipe Nipple Extension |

|

|

||

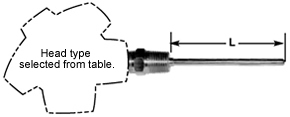

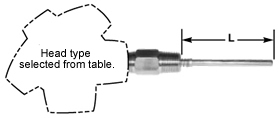

| Figure 2 |

RTD Assembly with 1/2″ NPT Process Fitting |

Figure 5 |

Spring-Loaded RTD Assembly with 1/2″ NPT Hex Fitting/Union Nipple Extension |

|

|

||

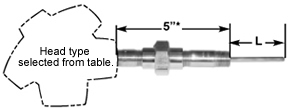

| Figure 3 |

Spring-Loaded RTD Assembly with 1/2″ NPT Process Fitting |

Figure 6 |

Spring-Loaded RTD Assembly with 1/2″ NPT Nipple/Union/Nipple Extension |

|

|

||

* For custom extension length, add desired length as suffix to basic order code. Variable lengths only available in figure 4, 5 and 6

Example: 5046, for 6″ long extension.

** Fitting/Extension shown in figures 1, 2, 3, & 5 only available in stainless steel.

– If connection head is not required, simply insert figure number as basic order code Example: 3

How to Order

| Pgs. 6-8 | – | Page 9 | – | – | Page 10 | – | TW Section | ||||||

| Basic Order Code | Sensor Diameter | Element | Tolerance | Temp. Range | Sheath Mate | Lead Conn. | “L” Length |

Options | Order Code for

Thermowell If required (see Thermowell section) |

||||

| 104 | 4 | A | 1 | B | 1 | C | 12 | 2AS | |||||

| Table A | Table B | Table C | Table D | Table E | Table F | Table G | Table H | Table I | |||||

| Type of Head | Head Material | Basic Order Code | |||||

| Figure 1 | Figure 2 | Figure 3 | Figure 4 | Figure 5 | Figure 6 | ||

|

Industrial Weatherproof Screw Cover Head |

Cast Aluminum | 100 | 200 | 300 | 400 | 500 | 600 |

|

Epoxy Coated Weatherproof Screw Cover Head |

Cast Iron | 102 | 202 | 302 | 402 | 502 | 602 |

|

General Purpose Weatherproof Screw Cover Head For Flip Top Style, add suffix “F” to basic order code |

Cast Aluminum | 104 | 204 | 304 | 404 | 504 | 604 |

|

Corrosion Resistant Weatherproof Screw Cover Head For Flip Top Style, add suffix “F” to basic order code |

Nylon | 106 | 206 | 306 | 406 | 506 | 606 |

|

CSA / ATEX / FM Approved Explosion Proof Head meets NEC Class I Div I Groups B, C, D Class II Div I, Groups E, F, G NEMA 4X, 7, 9, II2G, Ex d, IIC, Gb, II2 D, Ex tb, IIIC Db, IECEx |

Cast Aluminum | 108 | 208 | 308 | 408 | 508 | 608 |

| 316 Stainless Steel | 110 | 210 | 310 | 410 | 510 | 610 | |

RTD Assembly Specifications

| Sensor Diameter | Order Code | |

| 1/8″ | (.125″) | 2 |

| 3/16″ | (.188″) | 3 |

| 1/4″ | (.250″)STD | 4 |

| 5/16″ | (.312″) | 5 |

| 3/8″ | (.375″) | 6 |

|

Resistance 0°C |

Material | Temperature Coefficient/Alpha (a) | Order Code | |

| Single Element | Dual Element | |||

| 100Ω | Platinum | .00385Ω/Ω°C | A | 2A |

| 100Ω | Platinum | .003916Ω/Ω°C | B | 2B |

| 100Ω | Platinum | .003902Ω/Ω°C | C | 2C |

|

98.129Ω (100Ωnom-) |

Platinum Sama Standard RC21-4-1966 |

.00392Ω/Ω°C | D | 2D |

| 120Ω | Nickel | .00672Ω/Ω°C | E | 2E |

| 9.035Ω | Copper | .00427Ω/Ω°C | F | 2F |

| Accuracy at 0°C | Order Code | |

| ± .12% | Class B | 1 |

| ± .06% | Class A | 2 |

| ± .03% | Lab Grade | 3 |

| ± .02% | Lab Grade | 4 |

| ± .01% | Lab Grade | 5 |

| Temperature Range | Order Code |

|

-50 to +250 Deg. C -58 to +482 Deg. F |

A |

|

-50 to +400 Deg. C -58 to +752 Deg. F |

B |

|

-50 to +660 Deg. C -58 to +1220 Deg. F |

C |

| Sheath Material | Order Code |

| 316 SS | 1 |

| Alloy 600 | 2 |

| Alloy C-276 | 3 |

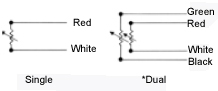

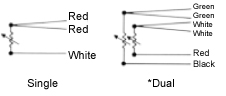

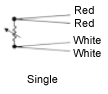

| 2-Wire | Order Code A |

|

|

| 3-Wire | Order Code B |

|

|

| 4-Wire | Order Code C |

|

|

|

Specify “L” in Inches Length Not required when Thermowell is used. |

Optional Connections

(For extended lead types)

Table I (options)

| Description | Order Code | ||

|

Spade Lugs for #8 Screw | L | |

|

Male Plug | M | |

|

The connectors shown are for 3-wire single element assemblies. Two – 2 Pin connectors mounted in tandem will be furnished for both styles of 4-wire single element assemblies. Dual element assemblies will have the same connector arrangements except Doubled. |

|||

|

|||

| Female Jack | F | ||

|

Watertight connector | 1/2″ NPT | W1 |

| 3/4″ NPT | W3 | ||

|

Watertight connector with lugs for #8 screws | 1/2″ NPT | WL1 |

| 3/4″ NPT | WL3 | ||

| Optional Mounting Fittings | ||

| Description | NPT | Order Code |

|

1/8″ | 1AS |

| 1/4″ | 2AS | |

| 3/8″ | 3AS | |

| 1/2″ | 4AS | |

| 3/4″ | 6AS | |

|

For FEP readjustable insert, replace “A” with “R” Example: 4RS |

||

| Optional Spring-Loaded Devices | |

| Description | Order Code |

|

Adjustable Spring |

FP 275 |

|

1/2″ NPT Double threaded adjustable hex bushing |

FP 240 |

|

1/2″ NPT single threaded adjustable hex bushing |

SSL |