Product and Ordering Information

Table 4

| Connectors / Fittings | Order Code |

|

*For longer lengths; replace “3” with desired length. |

B3* |

|

1/2″ npt x 1/2″ npt SS Double threaded bushing brazed to the sheath. |

SB |

|

1/2″ NPT SS threaded bushing brazed to sheath. |

FS4 |

|

1/2″ NPT x 1/2″ NPT SS Double threaded bushing spring-loaded to sheath |

SBS |

|

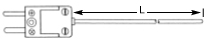

Standard male plug. |

M (400 F) |

|

HM (800 F) |

|

|

Standard female jack. |

F (400 F) |

|

HF (800 F) |

|

|

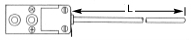

Dual male plug. |

DM (400 F) |

|

HDM (800 F) |

|

|

Dual female jack. |

DF (400 F) |

|

HDF (800 F) |

|

|

Miniature male plug. (for sheath diameters 1/8″ maximum) |

TM (400 F) |

|

HTM (800 F) |

|

|

Miniature female jack. (for sheath diameter 1/8″ maximum) |

TF (400 F) |

|

HTF (800 F) |

Table 4 continued

| Extended Leads / Lead Terminations | Order Code | |

|

20 AWG Wire Extension** |

Fiberglass Insulation | TG(X)* |

| Polyvinyl Insulation | TP(X)* | |

| FEP Insulation | TT(X)* | |

| Kapton Insulation | TK(X)* | |

| Polyvinyl Insulation, Twisted, Alum-Mylar Sheilded w/ Drainwire Grounded to the sheath. | TPZD(X)* | |

|

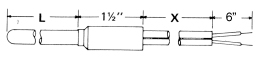

20 AWG Wire Extension Inside Stainless Steel Overbraid** |

Fiberglass Insulation | TGS(X)* |

| Polyvinyl Insulation | TPS(X)* | |

| FEP Insulation | TTS(X)* | |

| Kapton Insulation | TKS(X)* | |

|

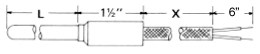

20 AWG Wire Extension inside stainless steel flexible tubing armor.** |

Fiberglass Insulation | TGA(X)* |

| Polyvinyl Insulation | TPA(X)* | |

| FEP Insulation | TTA(X)* | |

| Kapton Insulation | TKA(X)* | |

|

20 AWG Wire Extension inside polyvinyl covered stainless steel flexible tubing armor.** |

Fiberglass Insulation | TGP(X)* |

| Polyvinyl Insulation | TPP(X)* | |

| FEP Insulation | TTP(X)* | |

| Kapton Insulation | TKP(X)* | |

* Replace (X) with desired length in inches.

** Standard conductors are solid. For stranded conductors – Specify by placing “F” in the order code before length. Example: TGSF36. (Not available for “TPZD” option).

*** “DRIP loop” style T/C’s are available in armored lead options. Choose head option in the hardware section and add head order code as a suffix to the complete part number.

Table 4 continued

Terminal Heads

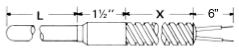

| Figure 1 | T/C Assembly Without Process Fitting |

|

|

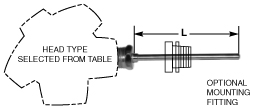

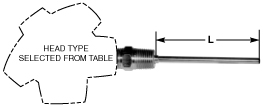

| Figure 2 | T/C Assembly w/ 1/2″ NPT Process Fitting |

|

|

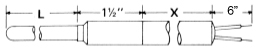

| Figure 3 | T/C Assembly w/ 1/2″ NPT Spring Loaded Fitting |

|

|

Table 4 continued

| Type of Head | Head Material | Basic Order Code | |||||

| Figure 1 | Figure 2 | Figure 3 | |||||

|

Industrial Weatherproof Screw Cover Head |

Cast Aluminum | 100 | 200 | 300 | |||

|

Industrial Weatherproof Screw Cover Head |

316 S.S. | 112 | 212 | 312 | |||

|

General Purpose Weatherproof Screw Cover Head For Flip Top Style, add suffix “F” to basic order code |

Cast Aluminum | 104 | 204 | 304 | |||

|

Corrosion Resistant Weatherproof Screw Cover Head For Flip Top Style, add suffix “F” to basic order code |

Nylon | 106 | 206 | 306 | |||

|

CSA / ATEX / FM Approved Explosion Proof Head meets NEC Class I Div I Groups B, C, D Class II Div I, Groups E, F, G NEMA 4X, 7, 9, II2G, Ex d, IIC, Gb, II2 D, Ex tb, IIIC Db, IECEx |

Cast Aluminum | 108 | 208 | 308 | |||

| 316 Stainless Steel | 110 | 210 | 310 | ||||